The corporate landscape is being swiftly transformed by digital twin technology, which presents unmatched chances for efficiency and creativity. Digital twins are notably transforming product development, allowing businesses to produce better things more quickly and affordably, according to a report.

Digital twin technology has an extensive influence. Digital twins, for example, have been shown to cut the number of preproduction prototypes required while also reducing overall development timeframes by 20 to 50 percent in product development.

By adopting digital twins during the product development process, some organizations estimate a 25% reduction in quality concerns, in addition to cost savings.

“„Estimates indicate that the market for digital twin technologies will expand at an exponential rate, with growth of over 60% per year over the next five years and an anticipated $73.5 billion by 2027.

The technology's capacity to enhance testing and validation, give more profound insights into product behavior, and use real-world data to guide product enhancements is what's fueling this expansion.

By utilizing digital twin technology, companies are not only improving the quality of their products and operations, but they are also putting themselves at the forefront of technical innovation. In this article, we will talk abouthow your businesscan benefit from digital twin technologyin detail.

What Is A Digital Twin?

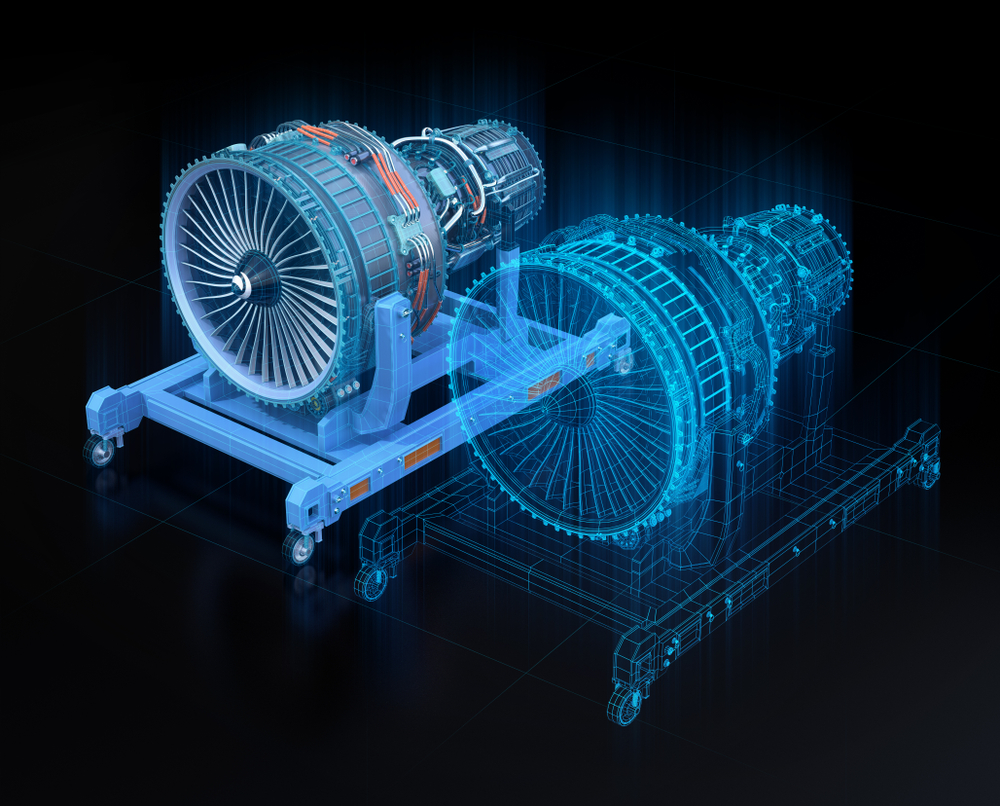

By building a digital duplicate of an actual system or process, digital twinning entails a number of tasks like testing, monitoring, integration, simulation, and maintenance. Digital twinning is a technique that improves the communication of digital and physical systems by synchronizing real-time activities with their digital equivalents.

Based on the Internet of Things (IoT), this technology installs sensors on tangible goods in order to gather data and enhance communication.

Digital twin technology was first introduced by NASA, which produced life-size models of the first spacecraft. These dummy models were used on the ground to simulate and identify problems that arose in orbit. Entirely digital simulations gradually superseded physical copies as the primary means of space exploration.

The first stages of developing a digital twin are completed by experts, often with backgrounds in data science or applied mathematics. The underlying physics of the physical system or item being duplicated is examined by these programmers. They create a mathematical model that can replicate the actual item in virtual space using the data they have gathered.

Input from sensors that collect data from the equivalent real-world item is intended for the digital twin. As a result, the twin can accurately reproduce the actual thing in real-time and offer insightful information about its functionality and possible problems.

A natural object prototype also serves as the basis for the development of the twin, providing input during the product's refinement process. Prior to the construction of any physical form, the digital twin may occasionally even serve as a prototype.

How Is Digital Twin Different From Simulation?

Although the terms "digital twins" and "simulations" are sometimes used synonymously, they have quite distinct meanings and purposes. Using CAD softwareor another relevant platform, we create simulations.

Its simulated paces allow us to locate it, but they might not be an exact match for an actual thing. On the other hand, we may use real-world sensor data to create a digital twin. It can accurately mimic a real-world system and can even periodically modify it.

We employ simulations at the design stage of the product lifecycle to assess and forecast the real-world behavior of our product. However, we employ digital twins to obtain information about the system or goods we now use, as well as business insights.

Types Of Digital Twins

Depending on what they're meant to mimic, the digital twins, or virtual replicas of goods and services, fall into one of three main categories;

Product Twins

The product twin is the first type of digital twin, in which the digital duplicate attempts to mimic distinct items. For instance, the manufacturing sector offers the most fantastic illustration of a product twin.

Therefore, before establishing the natural manufacturing processes, manufacturers frequently utilize a virtual prototype of the product to understand better a particular product and how the product would perform under different situations.

They are able to manage the final product better, comprehend how it works, and assist in making the required adjustments or enhancements thanks to the study of the digital duplicate of the virtual product.

Process Twins

The process twin is the following kind of digital twin. Wherein businesses digitize their processes in order to gain a better understanding of the process and its ramifications in different scenarios.

By building a process simulation, the company may enhance its production methods, make preventative maintenance possible, and minimize expensive downtimes. All of these factors contribute to a quicker, more scalable, more efficient process.

System Twins

A digital duplicate of the whole operating system (such as a factory) is produced in the third type of digital twin, known as a system twin.

The goal of the enterprises is to create a digital twin of the whole system in order to acquire insights into its operation and maintain the integrity of the system by analyzing every aspect of its functioning, from data extraction to processing, and by opening up new business opportunities.

Use Cases Of Digital Twins In Business

Cross-Functional Collaboration

We can periodically get operational data by using digital twins. Data is provided by it to enhance customer satisfaction, manufacturing, distribution, and process optimization. Sharing data between several departments, such as marketing, sales, and manufacturing, makes all of this feasible.

Workers in different domains can access the exact data for analysis. It facilitates enhanced and cooperative decision-making.

Manufacturing

Examples of digital twinning in manufacturing may be seen in a variety of contexts, including simulation, remote control, and asset monitoring using virtual objects.

Additionally, it adjusts and enhances processes, services, and products to meet the requirements and demands of customers. It supports companies in achieving both excellent customer satisfaction and long-term viability.

Design Of Products

One of the critical factors in the company's success is the potent designs of the items. Making the appropriate choice after careful consideration is therefore essential for product designs. A virtual version of a manufactured product may be created using digital twins, which gather data and aid in the development, testing, and validation of predictive analysis.

During the design process, engineers test several concepts using these virtual prototypes. It enables them to make the proper investments for a reliable prototype. It reduces the need for many concrete prototypes, production costs, and time.

Process Improvement

Businesses may monitor and assess processes under various performance circumstances and standards with the use of digital twins. It is beneficial to anticipate problems and identify them early on.

Digital twins allow us to convert assets into cost-saving and process-optimizing solutions. Additionally, we can forecast when equipment will require upgrades, replacements, or repairs, which helps to streamline the procedures.

Benefits Of Twin Technology In Business

Planned Maintenance

Digital twins can help organizations regulate their costs by assisting operators in anticipating when to replace outdated equipment and perform maintenance. For instance, an electric company may decide to repair and replace a specific number of outdated utility poles annually rather than waiting for equipment to wear out.

By using digital twin technology, they may avoid perhaps incurring those costs all at once by prioritizing which ones to take care of first and budgeting for them over several years.

This kind of procedure is made possible by the properties of digital twins, which contain comprehensive information about every asset, historical performance data, maintenance records, and analytics to forecast potential problems.

These qualities assist businesses in switching from a reactive to a proactive approach. This method is demonstrated in the video that follows.

Make Better Products

Before putting things into production, companies may test and confirm them with the use of digital twins. Engineers can design fictitious scenarios for complicated systems to examine how the machinery would function in particular circumstances.

They can make adjustments such that the product is nearly error-free when it is put into production. This feature not only improves product quality but also reduces the time and expense associated with in-person testing.

This technique might be more beneficial the more complicated the product being created. Consider the possibility that an automobile firm may design a virtual representation of a car that it hopes to construct.

The manufacturer may enhance the performance and design components of the car by testing it before it is constructed. With new automotive technologies like those found in electric cars (EVs), a market category that is expanding swiftly, this procedure is quite helpful.

Increased Productivity

Real-time system monitoring and control are made possible by digital twins, which improves operational efficiency. By anticipating maintenance requirements, they may minimize equipment downtime and increase its longevity.

Businesses may take proactive measures to fix problems before they become more severe and require expensive repairs or halts to operations thanks to this predictive maintenance capacity.

Cost Reduction

Through the elimination of the need for physical prototypes, reduced maintenance expenses, and efficient operation optimization, digital twins can result in significant cost savings. Additionally, they contribute to waste reduction and energy efficiency improvements, which, over time, can result in considerable cost savings.

Risk Mitigation

Digital twins assist firms in foreseeing future failures or difficulties by modeling various situations and outcomes, which reduces risk.

This capacity is beneficial in sectors like manufacturing, automotive, and aerospace, where anticipating product performance and possible breakdowns may avert expensive and hazardous consequences.

Data-Driven Decision Making

Digital twins produce large volumes of data, and these data may be examined to learn more about consumer usage trends, product performance, and operational inefficiencies. By using real-time data to influence decisions, this data-driven strategy helps firms optimize their operations and goals.

Customization And Personalization

Digital twins allow for the customization of items to fit unique client demands in industries such as manufacturing and retail. Businesses may offer customized goods without the usual expenses and hazards associated with bespoke production by modeling the performance of various adaptations.

Supply Chain Optimization

Entire supply chains may be modeled with digital twins, which offer insights into production schedules, inventory levels, and logistics. Businesses may streamline their supply chain processes, lower the cost of inventory, and accelerate delivery times with this all-encompassing approach.

Environmental Compliance And Sustainability

Digital twins help companies adopt more environmentally friendly business practices by streamlining operations and cutting waste. They may also assist businesses in adhering to environmental rules by tracking and reducing their resource and carbon footprint consumption.

Improved Client Relationship

Digital twins are a helpful tool for businesses to enhance consumer satisfaction. Digital twins of buildings, for instance, can improve how users interact with the area and increase user happiness and engagement in the real estate industry.

The Role Of Digital Twin Technology In Enhancing Organizational Agility

Globally, businesses are using digital twin technology more and more to keep up with the needs of today's ever-evolving business landscape. A digital twin is an electronic model made from digital data that simulates an actual system, process, or item. By building a virtual representation of an entity, this technology enables businesses to track, evaluate, and improve its performance in real-time.

Among the many advantages that digital twin technology offers businesses is more adaptability. Organizations are able to evaluate the consequences of changes more rapidly and make well-informed choices more swiftly by building a virtual model of an entity.

This enables them to react quickly to changes in the market and client demands. Furthermore, potential issues may be detected early on with digital twin technology, which enables firms to take preventative measures and make changes before they get out of hand.

Moreover, digital twin technology enables real-time data collection and analysis of enormous volumes for enterprises. This data can aid process optimization and decision-making. Organizations may improve productivity and efficiency by identifying inefficiencies and eliminating waste by evaluating data from a digital twin.

The use of digital twin technologies is transforming business operations and enhancing organizational agility. Organizations may evaluate the consequences of changes more rapidly and make well-informed choices more swiftly by utilizing this technology.

They can also gather and examine data in order to spot any issues and streamline procedures. To put it briefly, digital twin technology is a vital instrument for improving organizational agility and maintaining a competitive edge.

Future Of Digital Twin Technology In Business

By 2024, digital twin technology in business is expected to have undergone substantial development and expansion. A thorough understanding of the economic, worldwide, and national projections and analyses for this technology is offered by the most recent study on the Digital Twin and Teleoperations Market, which projects growth from 2023 to 2031.

The study covers a variety of applications, from aerospace and defense to energy and utilities. It divides the market into many categories, including parts twin, product twin, process twin, and system twin.

Several market segments are expanding rapidly, and top companies in these areas include Siemens PLM Software, General Electric, Autodesk, Oracle, and Dassault System. The demand for effective, technologically advanced solutions across a range of sectors is fueling the expansion.

In addition to stressing the fast digital transformation and the significance of digital twins and teleoperations in assuring supply chain resilience and business continuity, the research addresses the effects of COVID-19 on the market.

The report's 2021-2026 prediction period points to a strong development trajectory for the digital twin market. The study emphasizes the importance of investment opportunities, market economics, and technology developments. It also highlights the benefits and possible obstacles that organizations implementing this technology may face.

Fast expansion, technical innovation, and an increasing range of applications across multiple sectors characterize the future of digital twin technology in business in 2024. This development trend highlights how vital technology is to promoting resilience and corporate efficiency in an increasingly digital environment.

Frequently Asked Question

Is Digital Twin Technology Applicable In Supply Chain Management?

Absolutely, it can model and optimize entire supply chains, improving logistics, inventory management, and production scheduling.

Can Small Businesses Benefit From Digital Twin Technology?

Yes, small businesses can leverage it for efficient operations and product development and to gain a competitive edge, even with limited resources.

How Does Digital Twin Technology Integrate With IoT?

It synergizes with IoT by using real-time data from sensors and devices to update and refine the virtual models, enhancing accuracy and functionality.

Conclusion

In today's ever-changing digital world, knowing how your business can benefit from digital twin technology is essential. This cutting-edge technology, such as increased operational effectiveness, better product development, lower costs, and less risk, provides numerous benefits. Its capacity to offer data-driven decision-making, predictive maintenance, and real-time monitoring has the potential to change how companies run and compete entirely.

Additionally, the use of digital twin technology is essential for improving customer experiences and environmental initiatives. Its integration across sectors represents a significant shift in the direction of customer-centric, responsive, and efficient business models going forward.

Adopting Digital Twin Technology is about more than simply being up to date with technology; it's about exploring new possibilities and propelling your company into a successful and innovative future.